Udskæring i plastik/plexiglas

Laser teknologi skaber, med ekstrem nemhed, produkter, som et resultat fra brugen af maskindesign, fremstillet med stor omhu. Cutlite Penta laser systemer præstere, på ikke-metalliske materialer, opskæring af bestemte objekter, med en kompleks og meget detaljeret profil, som er umulig at opnå med skærende værktøjer, der anvendes i traditionelle forarbejdningsmetoder.

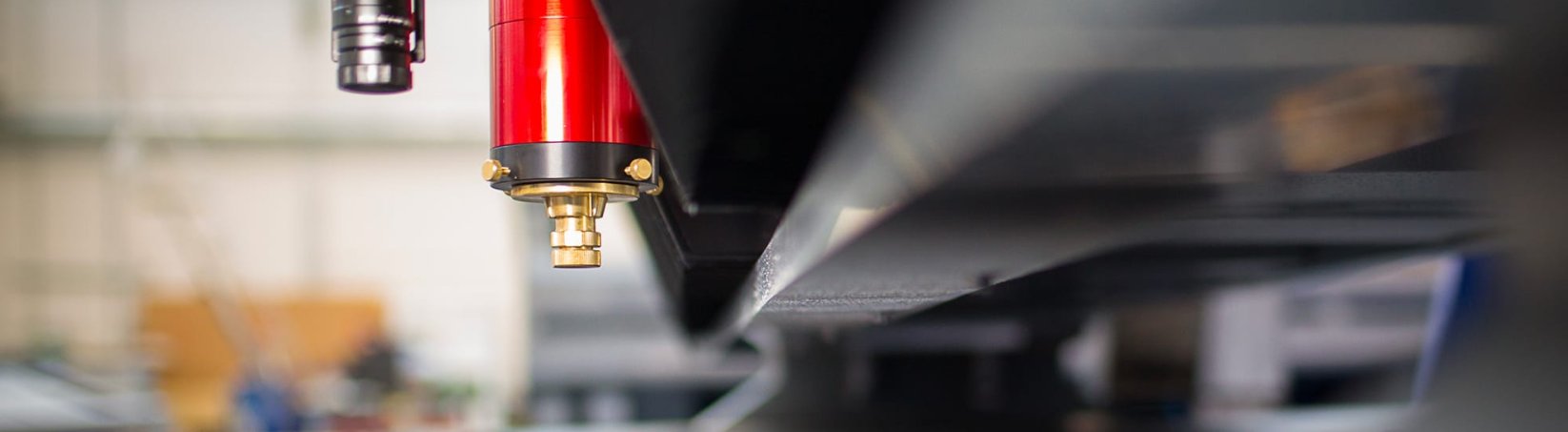

Takket være den ekstreme finhed, laseren udfører, er det muligt at lave tynde snit, med en bredde på nogle få tiendedele af en millimeter. Cutlite Penta maskiner realiserer komplekse flotte færdige produkter, skåret og graveret.

I udvalget af ikke-metalliske materialer, er der særlig interesse for bearbejdning af methacrylic (plexiglas …). Dette er en gennemprøvet teknologi i Italien og i verden, der altid møder nye og voksende applikationer, hvor som helst, præcision og kreativitet er nødvendig.

Cutlite Penta hjemmeside

The PLUS CP RF in the best solution in terms of affordabilityand efficiency taking the advantage from the small size of the whole system combined with the liner motors. The PLUS CP RF systems offer great accessibility to the working area of the machine allowing an ease loading/unloading of the processed material. The PLUS CP RF has two different available working areas: 3080×2050 mm and 2550×1550 mm.

In the catalog there is also a non-CP version of this machine and it is the PLUS RF3020.

Technical features

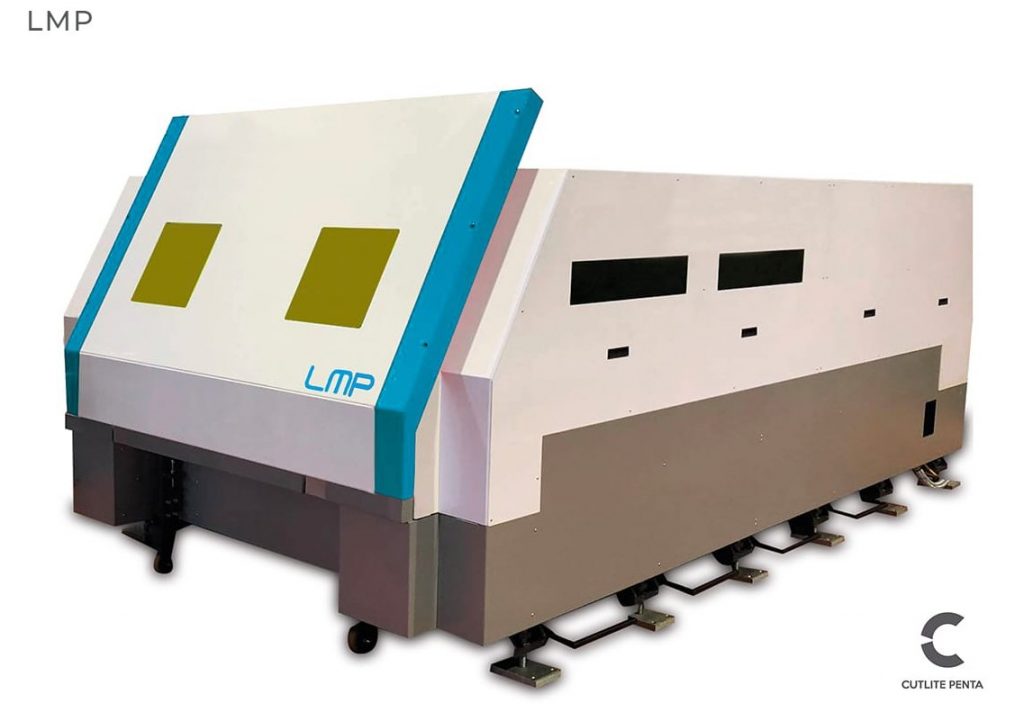

The new CO2 LMP laser cutting system is now part of the Cutlite Penta family. Designed to meet the market demands for small-sized machines with excellent speed and precision performance. The 1515 version can therefore represent the market entry-level system.

LMP meets this demand, maintaining the linear motor architecture and the all-in- one feature of the bigger Plus, as well as the same cutting head, with the possibility of designing and programming on board the machine thus making it a highly versatile system. Its installation takes maximum two working days.

STRENGTHS • Small and compact: Its footprint is slightly larger than its working area • Full of technology: linear motors, process sensors, radio frequency (RF) source Possibility of adding a galvanometer marking system • All in one: electrical units, laser source, control panel, all integrated This ensures high travel speeds and high precision in the marking process • Easy and fast installation : the machine is ready to start production with the customer in one day • CAD CAM software integrated on board the machine

Technical features

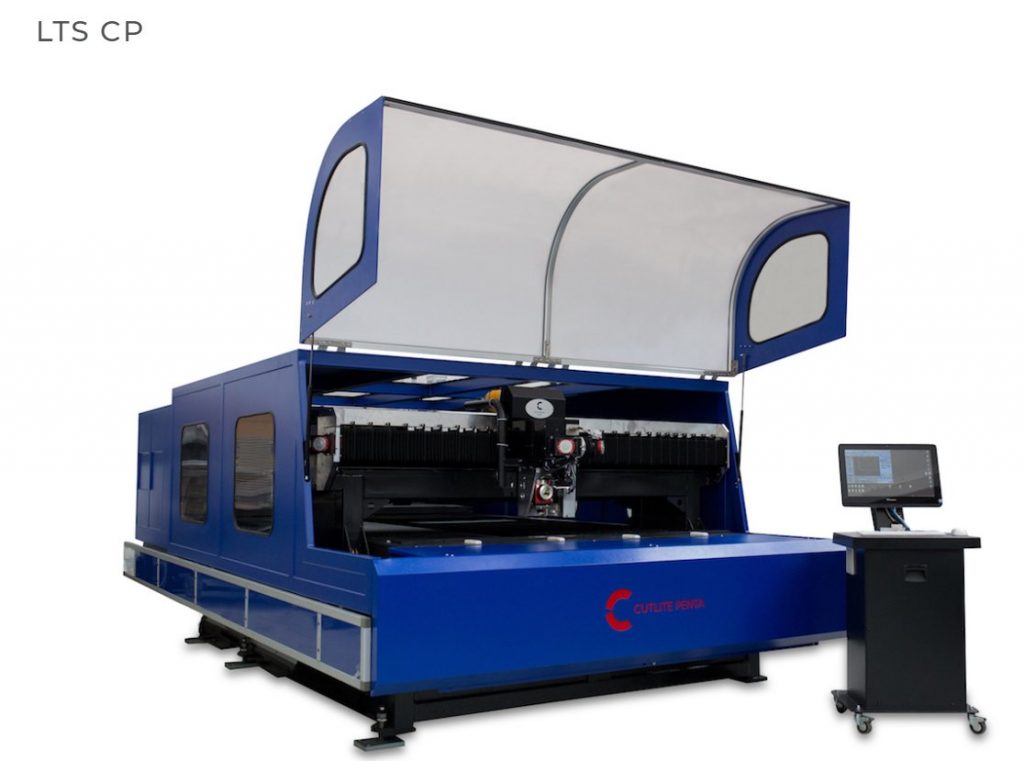

To achieve high dynamic the LTS CP system uses for the X axis handling a direct drive torque motor with hollow shaft stiffly coupled to a rotating nut ball. The linear motors movement in the Y axis enhances the dynamic performance in raster processing. Despite its small size, the machine can be equipped with the same optical devices as the other systems of the PLUS series: among these, our capacitive focusing head for cutting of metal sheets.